Hello everyone,

I’m Andy, a tea enthusiast.

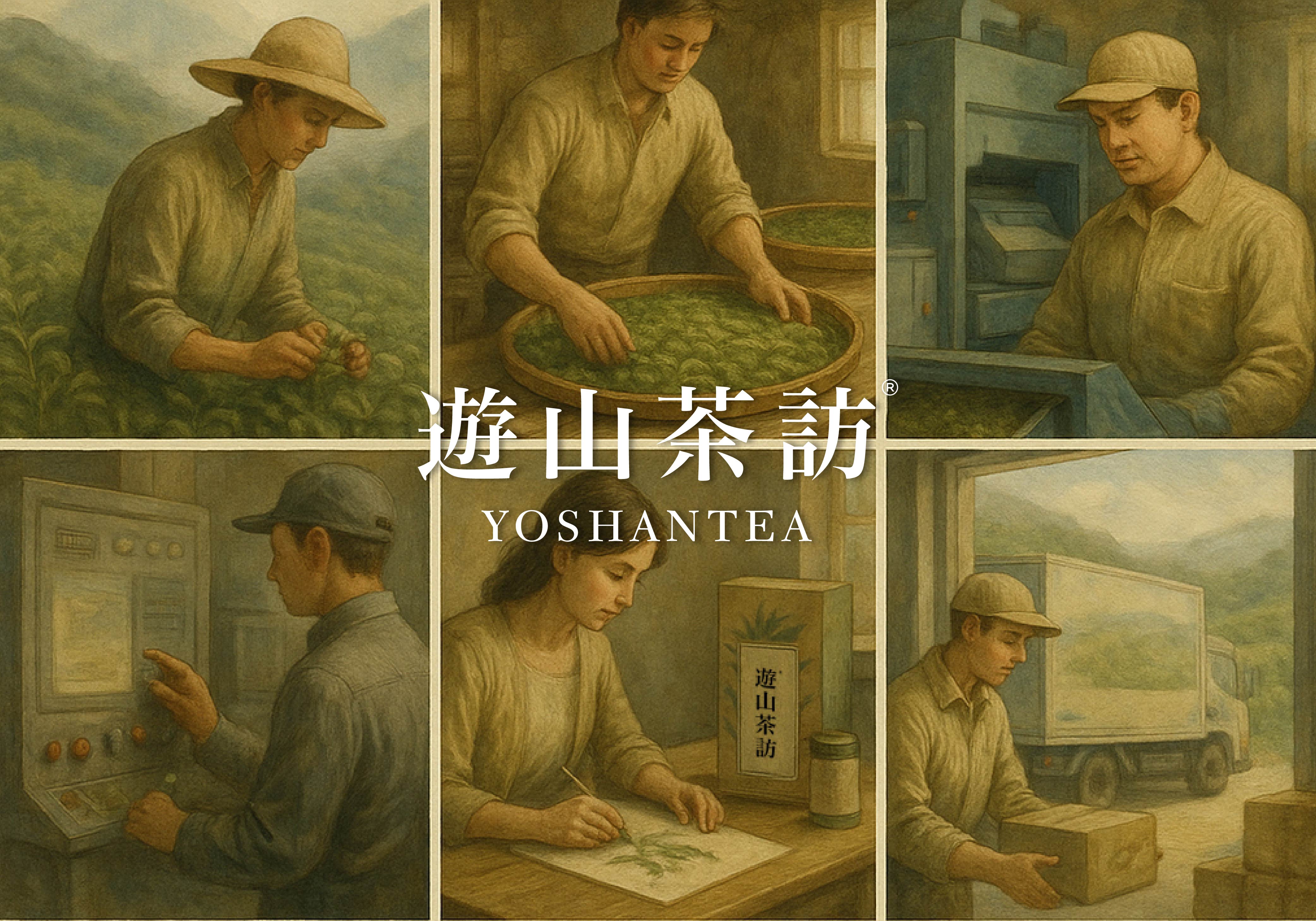

A truly high-quality cup of tea is never the work of a single person or factory.

It is the result of a collaborative effort across a complete industry chain, including farming, processing, inspection, design, logistics, and consumer experience.

Below are the key roles and stages involved in creating a great cup of tea:

1. Tea Farmers: The Starting Point of Quality

The quality of tea begins with how it’s cultivated.

Farmers must choose suitable cultivars and farming methods while managing fertilization, pest control, and harvest timing.

Whether their practices are eco-friendly and precise in picking directly impacts the flavor and safety of the fresh leaves.

2. Primary Processing Factories: The First Step in Building Flavor

After harvesting, fresh leaves must be processed immediately through withering, fixing, rolling, and drying.

These steps form the basic appearance and aroma of the tea.

The product from this stage, known as "mao cha" (rough tea), is still considered an agricultural product and may carry potential food safety risks.

3. Refined Tea Processors: The Key to Transforming Agricultural Goods into Food (Yoshantea)

This stage is handled by refined tea processors, who elevate the tea’s quality and flavor to meet food-grade standards.

Tasks include pesticide and highly polar pesticides (HPP) testing, stem removal, air and color sorting, foreign matter elimination, metal detection, blending, stacking, and roasting.

These steps are crucial for flavor consistency, sanitation, and international trade compliance.

Yoshantea serves as a leading example in this role, dedicated to scientifically managing the refinement process to upgrade Taiwan tea from a raw product to a high-quality food.

Additionally, refined processors also educate and support tea farmers and primary processors, offering production training, regulatory consulting, and quality guidance to improve the overall standard of "mao cha" (rough tea).

4. Equipment and Technical Partners: Behind-the-Scenes Support

Stable production processes rely on machinery and control systems that meet food safety regulations.

Equipment suppliers and technical teams ensure consistent production quality and help reduce food safety risks.

5. Packaging Designers and Material Manufacturers: Bridging Quality and Market

Good packaging increases brand recognition and helps consumers understand product value.

Design teams develop brand visuals and communication, while packaging manufacturers provide food-safe, eco-friendly, and sustainable materials.

6. Storage and Logistics Partners: Enabling a Reliable Supply Chain

Tea is highly sensitive to storage conditions.

High temperatures, humidity, or rough handling can degrade its flavor.

Warehousing partners must maintain temperature and humidity control, while logistics teams ensure proper packaging, temperature-managed shipping, and delivery tracking to preserve quality during transport.

7. Pest Control Specialists: The Foundation of Food Safety

Poorly managed production or storage environments can attract pests or contamination.

Pest control partners implement foreign object controls, schedule routine inspections, and carry out targeted sanitation procedures to meet international hygiene standards like HACCP and FSSC22000.

8. Testing and Certification Bodies: Independent Scientific Gatekeepers

To ensure safety and compliance and avoid biased self-assessment, third-party laboratories conduct tests for pesticide residues, heavy metals, and microorganisms.

Certification bodies help build and maintain systems like ISO 22000 and FSSC22000, enhancing transparency and continuous improvement.

9. Consumers: The Final Force That Drives the Industry

Consumers are not just tea drinkers; they’re the ones providing value feedback across the industry chain.

Their choices and responses shape brand direction, market standards, and the industry's evolution.

Consumers willing to support safe quality, subtle flavor, and brand value are the greatest driving force behind the development of Taiwan’s tea industry.

Conclusion

The sustainability of the tea industry cannot rely on a single company, farmer, or system.

Every link requires professionalism, trust, and long-term cooperation.

At Yoshantea, we believe that only when everyone from source to consumption is committed to improvement can Taiwan tea truly be understood and recognized by the world.

This is the most precious part of a cup of tea—it's not just a display of flavor, but a crystallization of mutual effort and benefit.

#teasupplychain #teaproduction #teafarming #foodgradeprocessing #packagingdesign #tealogistics #thirdpartytesting #fromfarmtocup #teacollaboration