Hello everyone, I'm Andy, a tea enthusiast.

Managing tea is both a science and an art.

How can we build a modern and systematic management system within the traditional tea culture?

Such a system can improve product quality and food safety, streamline team operations,

and even reduce friction and complaints among employees.

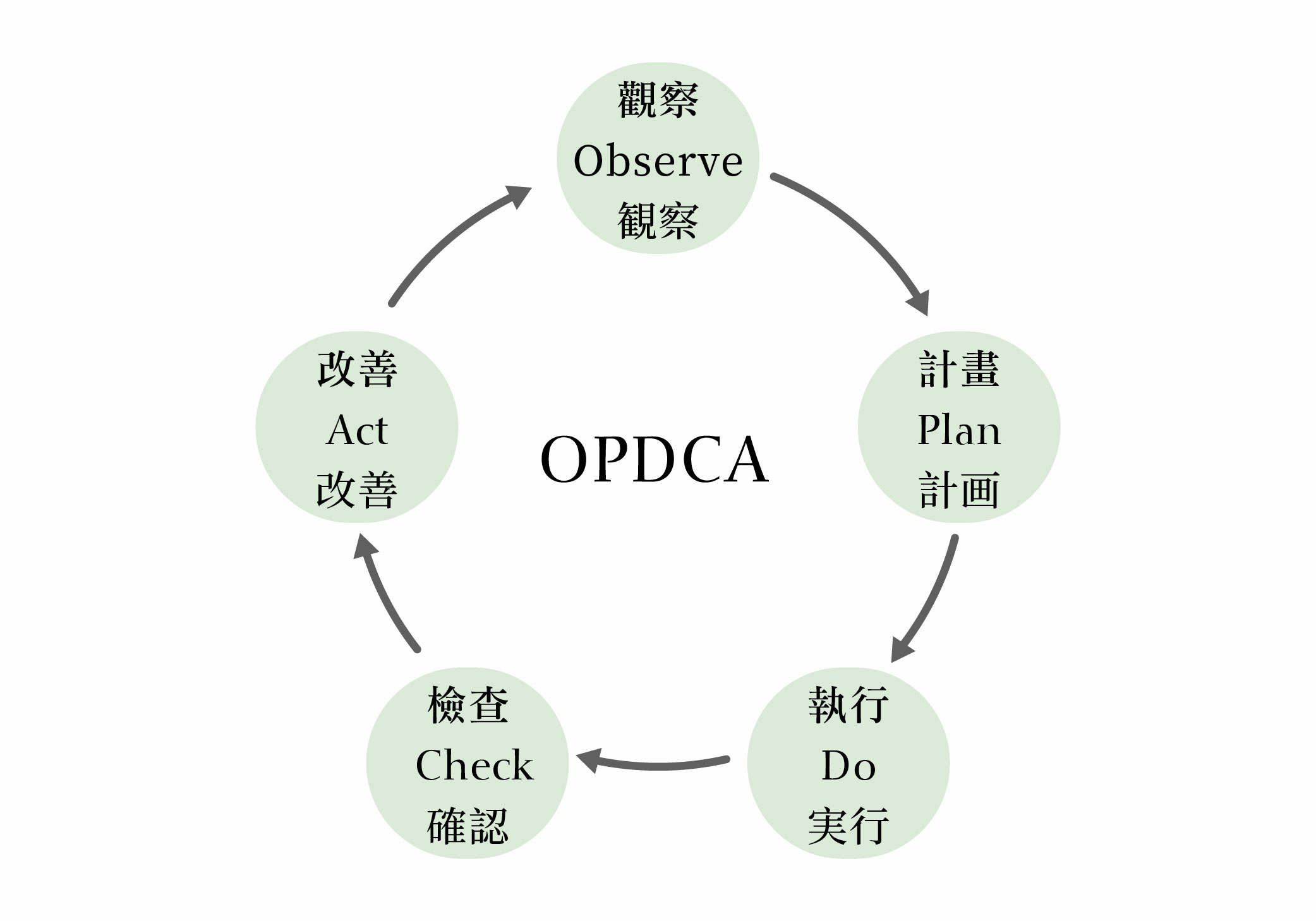

Among many management tools, the PDCA cycle is the most well-known model.

But today, I want to share with you an even more practical and field-friendly evolution of it:

The OPDCA Management Method.

What is the PDCA Cycle?

PDCA stands for:

- P – Plan: Set improvement goals and design action plans

- D – Do: Implement the planned actions

- C – Check: Observe the results, check if expectations are met, and identify problems

- A – Act: Adjust and standardize based on the findings

The core idea of PDCA is continuous improvement — small steps forward to steadily raise quality, efficiency, and management standards.

Benefits of Using PDCA

- Standardize Operations: From raw material sourcing, tea processing, packaging to shipping, PDCA can establish standard procedures

- Enhance Food Safety Management: When combined with HACCP, ISO22000, and FSSC22000 systems, it effectively prevents risks

- Build a Culture of Continuous Improvement: Constant optimization of processes, equipment, and training fosters a progressive team

- Ideal for SMEs and Succession Teams: Easy to learn, understand, and promote

Why Choose “OPDCA” Over Just PDCA?

In real-world operations, many successors or internal managers often skip the observation phase and jump straight to rule-setting.

For example:

- Changing production schedules without fully understanding the tea factory layout

- Replacing tools or packaging methods without knowing employees’ workflow habits

- Modifying product standards without participating in tasting processes

These errors stem from the lack of the “Observation” step.

Therefore, I recommend using the more complete OPDCA model.

The Five Steps of OPDCA

- O – Observe: Visit the site, watch the process, listen to employees. Understand the current state and pain points. No observation, no management

- P – Plan: Based on observations, draft improvement plans with clear goals and steps

- D – Do: Pilot the new plan or system in practice

- C – Check: Collect data and feedback to assess the outcome

- A – Act: Adjust accordingly to continuously evolve the system

Observation Is the First Step in Tea Management

Managing tea is not just about handling products and equipment — it's about people and culture.

When team members feel calm and happy, food safety systems are easier to implement,

and team operations flow naturally and smoothly.

Hope this information is helpful to you.

See you next time.

#yoshantea #taiwantea #dongdingtea #oolongtea #teafacotry #FSSC22000 #safetea #teamanagement #OPDCA #qualitymanagement