Hello everyone,

I’m Andy, a tea enthusiast.

Food safety incidents occur frequently.

While tea itself is unlikely to pose direct health risks,

once it enters the food supply chain,

a complete traceability system becomes essential.

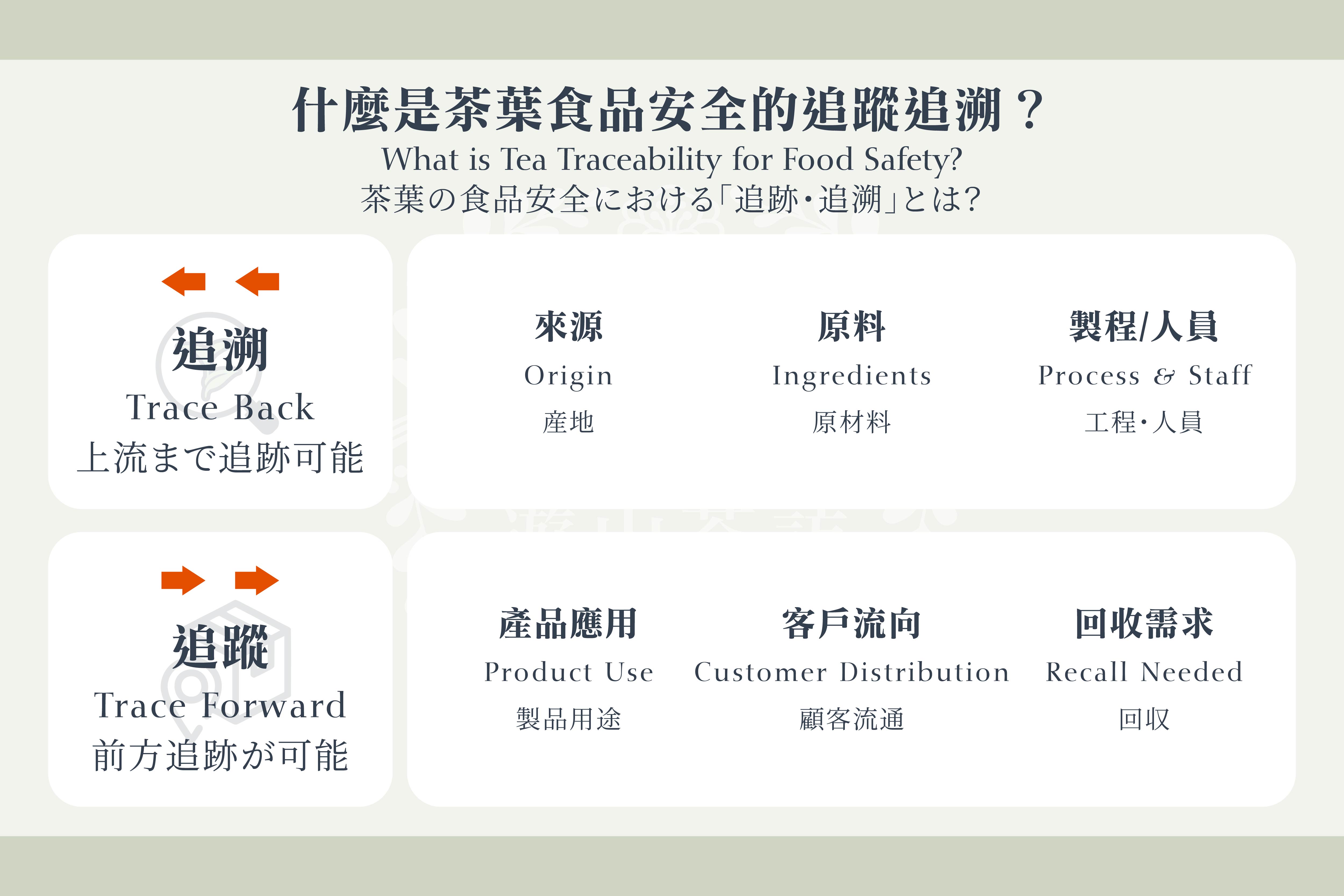

What is Tea Traceability for Food Safety?

Traceability refers to the ability to trace a product's source in the event of a problem (tracking backward),

and to identify where the affected product was distributed (tracking forward).

Tracing (trace back) refers to investigating from the present to the past:

identifying the origin of the problematic tea,

the raw materials used,

and the processes and personnel involved.

Tracking (trace forward)refers to following from the past to the present or future:

determining which products used the same batch of raw materials,

where they were distributed,

and whether a recall is necessary.

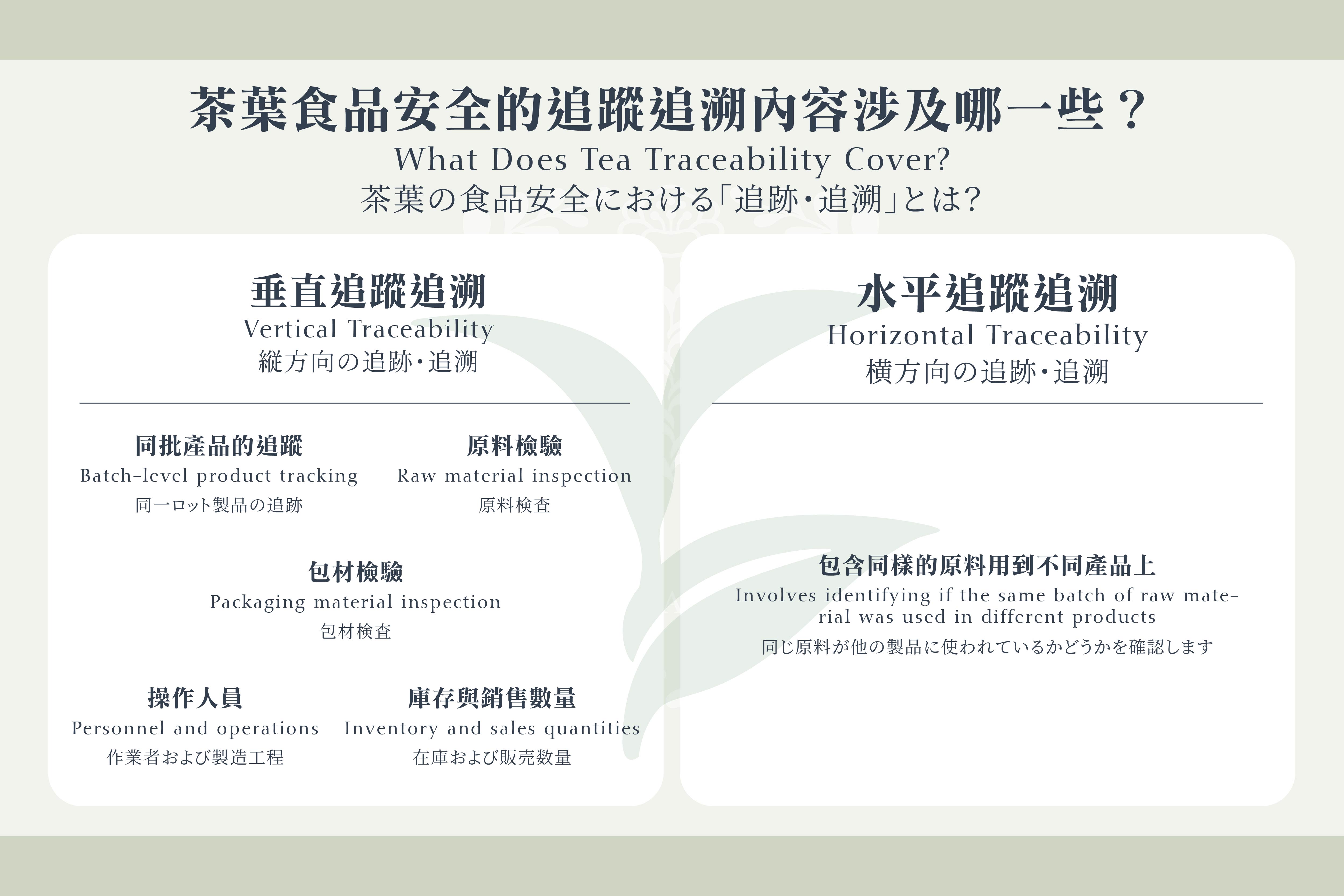

What Does Tea Traceability Cover?

It involves both vertical and horizontal tracking.

Vertical Traceability Includes:

- Same Batch Tracking:

Includes batch numbers, production dates, packaging specifications, and quantities.

If an issue arises with one package, the system can identify how many of the same batch are still in the market.

- Raw Material Inspection:

Covers tea leaf source, origin, incoming batch number,

and test data for pesticide residues, heavy metals, etc.

Helps determine if the issue is linked to a specific origin.

- Packaging Material Inspection:

Involves packaging batch numbers, food-contact material tests,

and whether the same packaging was used in other products.

- Operational Staff:

Includes staff on duty that day, work shifts,

and any abnormal operations or deviations in the production process.

- Inventory and Sales Volume:

Covers production quantity, stock levels, shipped quantities, and sales destinations.

This helps assess whether a recall is necessary and its scope.

Horizontal Traceability:

Involves identifying if the same batch of raw material was used in different products.

For example,

a single batch of tea leaves may be packaged into different weight formats,

or used in various product types or gift sets.

If the raw material is found to be problematic,

all products using that batch must be included in the assessment.

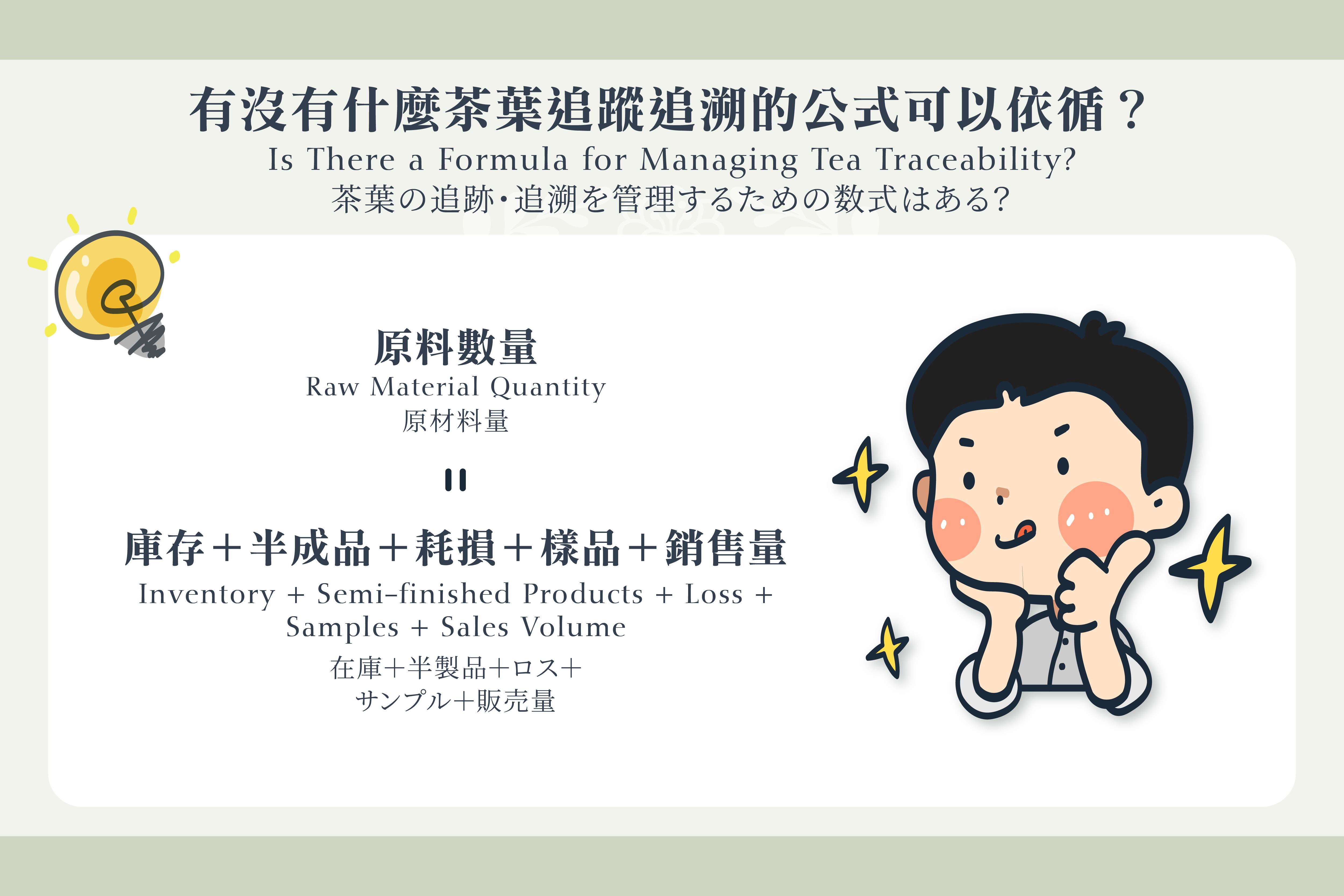

Is There a Formula for Managing Tea Traceability?

Yes, there is a basic formula used in practical management to verify traceability completeness:

Raw Material Quantity = Inventory + Semi-finished Products + Loss + Samples + Sales Volume

If the numbers don’t add up,

it means there’s a gap in traceability.

Common mistakes include:

- Raw materials used in other products

- Incorrect incoming quantities

- Unrecorded sample usage

- Process losses differing from estimates

- Theft

Is Tea Traceability Required by Law?

In most cases, yes.

Tea importers and food businesses with capital over NT$30 million

are legally required to implement traceability systems.

Even if a business does not meet the mandatory threshold,

when a food safety incident occurs,

authorities will still demand complete traceability data.

In short,

regardless of the system requirements,

once an issue occurs,

traceability is non-negotiable.

That’s all for today’s sharing.

Hope this has been helpful.

See you next time!

#yoshantea #taiwantea #dongdingtea #oolongtea #teafacotry #FSSC22000 #safetea #foodsafety #teatraceability #supplychain #trackandtrace #teaqualitycontrol